With almost four years of dedicated labour, the students’ project Utkarsh has the potential to improve the lives of women entrepreneurs by assisting them in improving their abilities and empowering them to take charge of their lives. In addition, the women entrepreneurs might save 90,000 gallons of water and 1,200 kg of food waste from ending up in landfills. As a result, greenhouse gas emissions linked with food waste are reduced, food availability is increased, hunger is reduced, and money is saved.

Food wastage is among some of the emerging problems that the world is facing. According to the latest Food Waste Index Report 2021, around 931 million tons of food waste was generated in 2019 globally. Meanwhile, 690 million people were suffering due to starvation. The report also estimates that an individual in India throws away 50 kg of food in a year. Looking at the numbers, it is of no surprise that such practices of food wastage have substantial environmental, social, and economic impacts.

Looking at such a grim issue, the students of Enactus Aryabhatta of Aryabhatta College in 2016 started an initiative called Project Utkarsh, under which pulp of different fruits or vegetables is used to make chips.

To get a better understanding of the project and how it has been able to impact the environment, The Earth View spoke with Sahej Kapoor, president of Enactus Aryabhatta and a 3rd-year student of Aryabhatta College.

Talking about the project, its products, and the working process, Sahej explained that the name of the project is Utkarsh and the product being manufactured under it is called Veggitos. These are chips made out of the pulp which the team collects from fruit vendors and comes in three flavours – Carrot, Beetroot, and Spinach as of now.

“We are trying to expand the variety of our products and not limit ourselves to food items only. For instance, coir mattress can be made out of coconut husk, and different colours can be extracted from pomegranate seeds and beetroot pulp.” This way the team is trying to minimise food wastage and manufacture several kinds of products out of it.

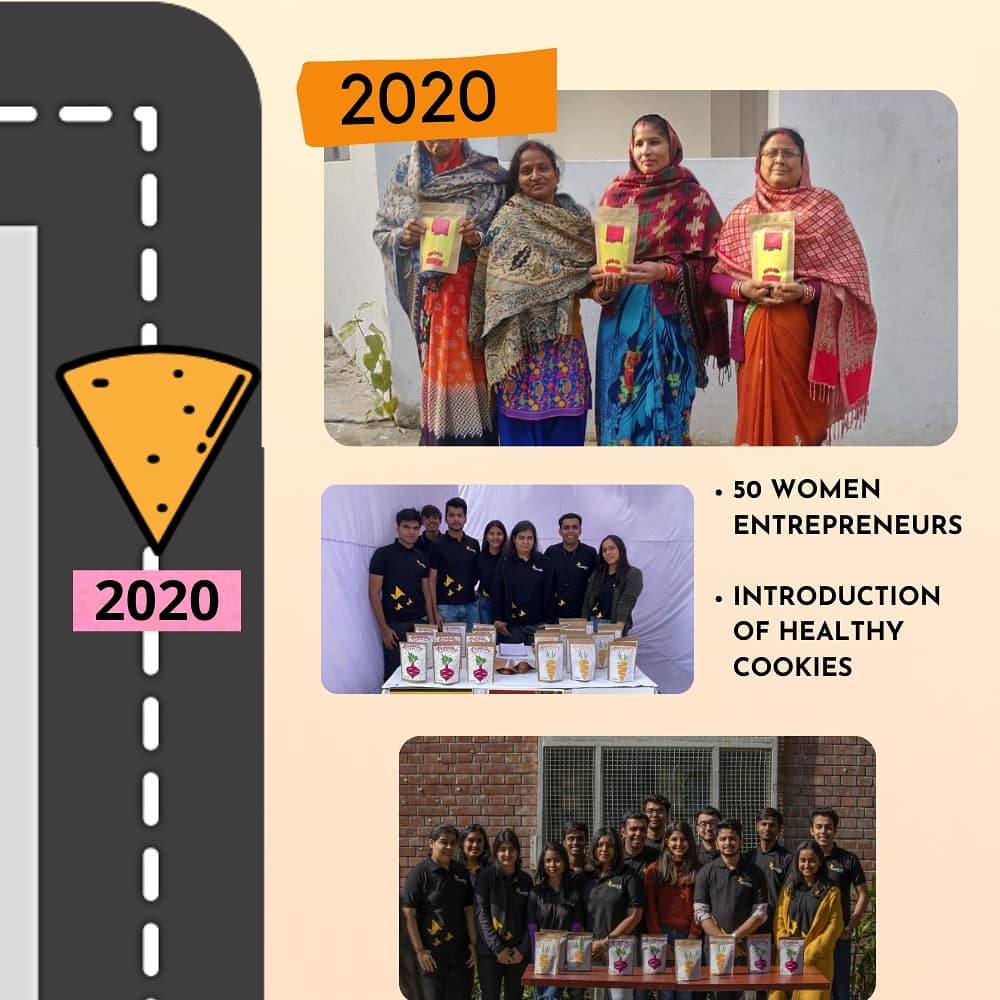

Veggitos was the product with which they launched the project and has generated a good amount of revenue. The project employs underprivileged women as beneficiaries to help them find a source of income and aid them economically. To sign up more beneficiaries and teach them how to make chips, the team has been reaching out to various NGOs. “As of now more than 50 women are working under the project and we are planning to increase the number.”

Talking about the process and machines used, he elaborated that “for making the chips, three types of flours are used – wheat, corn, and rice flour. We mix them in a fixed proportion as each flour has its significance and is converted into a dough. Then spices and powders are added to it, such as onion powder, garlic powder, chilli powder, and salt, to give it flavour. After that, the vegetable or fruit pulp, and water is added to the mix. The dough is rolled into thin sheets and brushed with olive oil, followed by giving it shape. In the end, it is baked in the oven for 20 minutes at a fixed temperature to make sure it is cooked and crispy.”

As the project involves gathering pulp from fruit vendors to make savoury snacks, the hygiene of the pulp holds the topmost priority. So, while talking about hygiene, Sahej said that “We have provided clean containers to the fruit vendors from where we collect the pulp. This method quality, as well as hygiene of the pulp, is maintained. Since we have been in collaboration with these vendors for years, they are like a part of the project as well and know how it works which helps in maintaining the hygiene of the pulp,” In addition, “we have Food Safety and Standards Authority of India (FSSAI) Certificate, which is mentioned at the back of the chips packet and we have supplier license as well, so we can easily supply these chips anywhere.”

Because of the pandemic, markets all over the globe have been at a standstill. With little hope of recovery because of the uncertain conditions, production and sales of products must have been a huge struggle to cross. Discussing the average sales and production of their product, Sahej shed light on their journey. Before the pandemic, the women entrepreneurs could sell hundreds of chips packets in three days because they employed different methods to sell their products. They went to college fests to put up their stall, visited different parts of the city like Dilli Haat, and took up online orders. With such varied platforms, a good number of chips were sold and the women could collect an acceptable amount of revenue. But with the pandemic and everything in lockdown, the women entrepreneurs could not sell the chips in the same quantity. Though “the chips are commercially available online and we deliver pan-India.”

With such a great initiative, it only makes sense if the project ties up with grocery stores to expand their reach further into the field. “We are in contact with companies such as SustainKart and GoingZero, which are online stores and will soon start selling our products,” says Sahej.

Sahej ended the conversation with a message for his fellow youth that “the practices we follow in our everyday life leave a huge impact on the environment. The things we don’t even pay attention to can ultimately contribute something to the bigger picture. So, I encourage others to be more conscious about what they are consuming, how sustainable making it is, and who will get the benefit out of the product.”

– Akansha Jain