Air pollution is a major health concern in India. According to a recent study, at least 140 million people in India breathe air that is 10 times or more over the WHO safe limit and 13 of the world’s 20 cities with the highest annual levels of air pollution are in India. When it comes to air pollution, we often think of exhaust emissions from vehicles, chimneys and factories as being the primary cause. However, such emissions have been regulated for years. There are far more severe sources of air pollution, which happen unregulated, such as the burning of tyre pyrolysis waste.

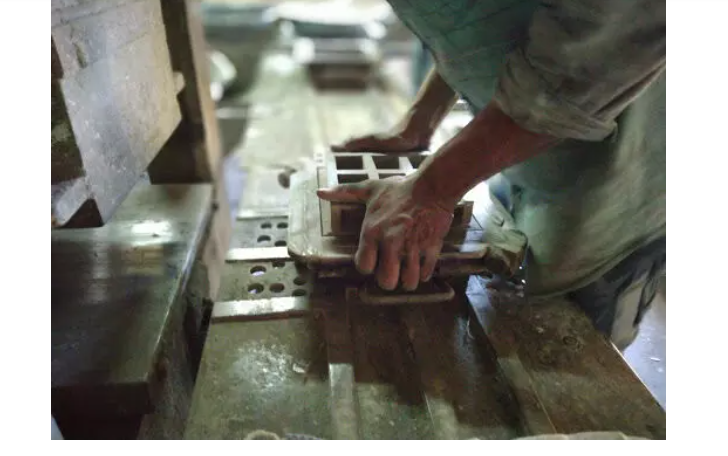

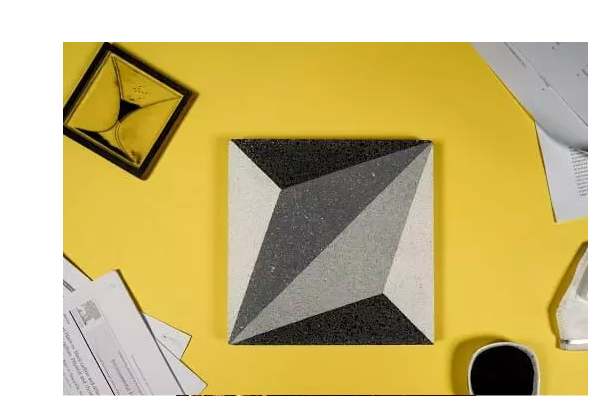

Carbon Craft Design, a Goa-based startup, has come up with a unique solution to reuse recovered carbon black, a byproduct produced by burning tyres. The startup sources waste carbon from various capture/collection companies such as Tyre Recycling factories and processes it at their facility to make it application-oriented. The processed carbon is then mixed with materials like waste marble chips, marble powder, cement. Then, with the help of traditional craft workers, the mixture is shaped into a monochromatic tile.

Tyre recycling factories, on average, generate around 15 lakh kgs of recovered carbon waste every year. If not repurposed, brick kilns use this material as cheap fuel, which deteriorates the quality of the air in surrounding areas.

Speaking to The Earth View, Tejas Sidnal, Founder of Carbon Craft Design, said, “According to the World Green Building Council, the building and construction industry is the largest consumer of raw materials and is responsible for 39% of total energy-related carbon emissions. If 1% of this industry consumed the waste recovered carbon black as a resource,

the impact would be phenomenal and would prevent it from being a cheap fuel material.”

There are two ways by which tyre waste can be dealt with. They can either be burned in the open, a process is known as open incineration or pyrolytically degraded at pyrolysis plants. While the former is prohibited, the latter is considered a safer way to break down the tyres. A byproduct of the pyrolytic degradation process is tyre pyrolysis waste called Recovered Carbon Black (RCB). “We realised that there are various methods to capture/collect pollution, but the next big question is what to do with the resulting carbon”, said Tejas Sidnal.

A carbon tile is the first such tile, made with upcycled carbon by using waste carbon as a resource. In addition to that, the process consumes one-fifth of the energy required to manufacture vitrified tiles. The company settled on tiles after having unsuccessfully experimented with bricks and facades in the past.

He further said, “We chose to go with tiles because they are commercially scalable, have some design value and people would pay for them as well.” Each square foot of tile produced prevents around 30,000 litres of air from being polluted. Having manufactured around 5000 sq. ft of tiles, the company has prevented around 150,000,000 litres of air from being polluted so far. The pandemic has kept the market for carbon tiles from reaching its true potential. The tiles are currently priced at Rs 300 per square foot, which is slightly more than the price of mass-produced vitrified tiles. However, Sidnal believes that scaling up operations would solve the problem. He said, “If we’re able to scale up, we’ll be able to get the price to half of what it is right now, which would make us more competitive in the tile market.” A chunk of the orders currently come from the B2B segment, with Adidas being one of their major clients. The startup also has plans to expand its range by adding products such as outdoor tiles, home decor accessories, among others. “Waste carbon has a variety of applications. It can be used to create several products ranging from inks to rubbers to thermoplastics. It all depends on how many people are ready to invest in repurposing the material “, said Sidnal as he signed off

.